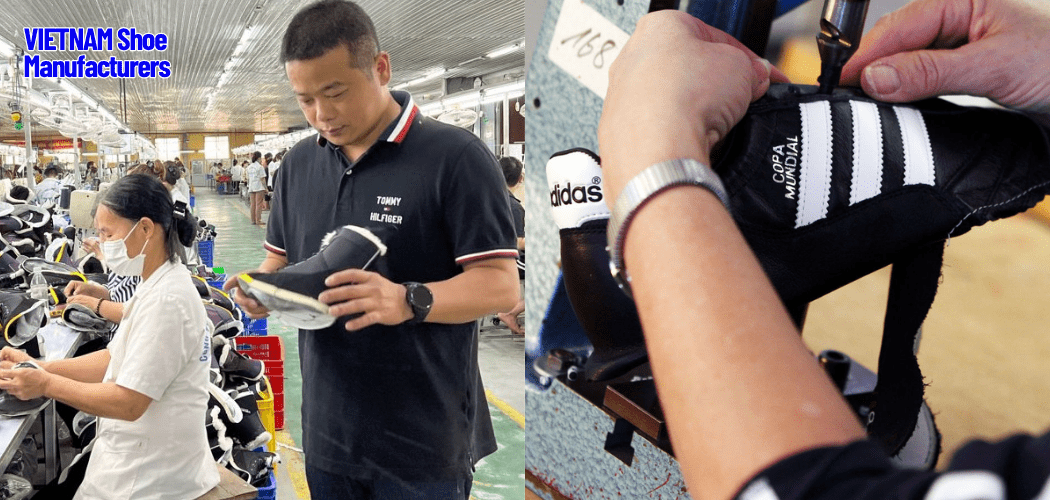

Design and prototyping are at the heart of premium footwear manufacturing. At [Vietnam Shoe Manufacturers], we specialize in transforming concepts into market-ready products through cutting-edge 3D design, meticulous sample making, and precision mold creation. With Vietnam’s rising reputation as a global footwear hub, our team stands at the forefront—delivering quality, customization, and efficiency for international fashion brands, importers, and startups.

Vietnam is no longer just a low-cost manufacturing destination. It is a thriving ecosystem of custom shoe manufacturers, known for craftsmanship, innovation, and responsiveness. Whether you’re launching a new sneaker line or scaling a private-label boot collection, Vietnam is the smart choice—and we are your strategic partner.

Why Choose Vietnam Shoe Manufacturers for Design & Prototyping?

Choosing the right partner for footwear development can significantly impact your brand’s success. Here’s why global brands trust us:

- End-to-End Capabilities: From concept sketches to final molds, we manage every stage of the design & prototyping process in-house.

- Global Quality Standards: Our processes align with international norms and certifications, ensuring your products are retail-ready for global markets.

- Diverse Product Expertise: Sneakers, casual shoes, boots, sandals, and athletic footwear—we’ve developed prototypes across a broad spectrum.

- Scalable Solutions: We accommodate both low MOQ (ideal for startups) and large-scale orders for established labels.

- Sustainable Options: As eco-friendly shoe manufacturers Vietnam, we offer recyclable materials, water-based adhesives, and sustainable practices.

Our Design & Prototyping Process: From Vision to Viable Product

Our structured and transparent process ensures a smooth journey from idea to high-quality footwear prototype:

1. Concept & 3D Design

Our process begins with your vision. Our in-house design team uses advanced 3D software to create precise digital mockups of your shoe concept. This stage allows for:

- Virtual sampling without material waste

- Detailed design iteration before physical production

- Speed-to-market by reducing manual rework

We collaborate closely with you to refine materials, shapes, and aesthetics—whether it’s for a high-fashion heel or a performance athletic shoe.

2. Sample Making

Once the digital design is finalized, we move to sample development:

- Material selection: Leather, synthetics, mesh, rubber, EVA, and more

- Handcrafting & assembly: Using production-grade methods for accuracy

- Fit & function testing: Ensure comfort, durability, and performance

This physical prototype helps you evaluate look, fit, and overall appeal before mass production.

3. Mold Creation

Precision molds are critical for consistent mass production. We:

- Use CNC and 3D printing technologies for accurate mold fabrication

- Calibrate based on your size range and construction method

- Offer flexible mold ownership options for private label clients

This ensures a seamless transition from prototype to mass production in our footwear factory Vietnam.

Quality Standards & Certifications

Our factory follows strict quality protocols and maintains international certifications including:

- ISO 9001 – Quality Management System

- ISO 14001 – Environmental Management

- REACH-compliant materials

- Social compliance audits (BSCI, WRAP, or SEDEX, upon request)

Every prototype undergoes internal QA checkpoints to ensure your shoes not only meet but exceed industry standards.

Customization & Order Flexibility

We know every brand has unique needs. That’s why we offer:

- Private Label Services: Develop your brand’s unique identity.

- Custom Branding: Logos, labels, embroidery, outsole design, and packaging.

- Flexible MOQs: Start as low as 300-500 pairs per style.

- Large-Volume Scalability: For global distribution and retail chains.

Whether you’re a boutique brand or an established retailer, we provide the same level of design precision and service.

FAQs: Design & Prototyping at Vietnam Shoe Manufacturers

Q: How long does the prototyping process take?

A: From concept to mold, it typically takes 3-5 weeks, depending on complexity and revisions.

Q: Can you work with my own designs?

A: Yes! We can work from your sketches, CAD files, or reference samples.

Q: Is mold creation included in the prototype fee?

A: Mold creation is billed separately but is quoted transparently upfront.

Q: What materials do you support for prototypes?

A: We source high-grade leather, vegan materials, recycled synthetics, rubber, PU, mesh, and more.

Q: Are prototypes made using the same methods as mass production?

A: Yes. We use production-grade tools and techniques for accurate evaluation.

Partner with Vietnam’s Trusted Footwear Innovators

At [Vietnam Shoe Manufacturers], we go beyond production—we co-create your product’s future. Our design & prototyping services are tailored to support global footwear innovation with local expertise.

Whether you’re launching the next trend in sneakers, seeking private label shoes from Vietnam, or looking to partner with boot manufacturers Vietnam, we’re ready to help bring your vision to life.

Call to Action

Ready to turn your footwear ideas into reality?

Contact us today to schedule a design consultation or request a prototype quote.

👉 [Contact Us] | [Request a Quote] | [Email: [email protected]]

Relevant Keywords (included naturally in content):

- Vietnam Shoe Manufacturers

- custom shoe manufacturers Vietnam

- athletic shoe manufacturers Vietnam

- casual shoe manufacturers Vietnam

- sneaker manufacturers Vietnam

- boot manufacturers Vietnam

- private label shoes Vietnam

- footwear factory Vietnam

- eco-friendly shoe manufacturers Vietnam

- shoe prototyping Vietnam